Montekord Machines nabízí

Automatizace

Poskytujeme komplexní služby v oblasti průmyslové automatizace, robotizace a výroby jednoúčelových strojů, vč. modernizace stávajících zařízení.

Programování

Nabízíme vám kapacity našich programátorů za takové ceny, aby to dávalo smysl pro obě strany. (PLC, robotika, SCADA a DATA, kamerové systémy)

O společnosti

Základem je zkušený tým šikovných lidí, které baví práce

Stavíme na myšlence přístupu původních majitelů, kteří začínali ve 2 lidech a při rozvoji firmy rozvíjeli tým spolupracovníků. S každým novým projektem posilovali jednotlivé úseky, které dnes dohromady tvoří komplexní celek. Základnou byla konstrukce a projektové řízení, ke kterému postupně vybudovali tým zkušených mechatroniků a elektrikářů. Tento tým doplnili o šikovné programátory, kteří dnes dávají život a duši vznikajícím strojům a aplikacím.

Firma si zakládá na kreativním přístupu všech zaměstnanců na všech pozicích, kteří originálním a pro zákazníka efektivním způsobem realizují investiční záměry.

V práci vyznáváme volnou pracovní svobodu a nesvazujeme striktními nařízeními a přístupu. Chceme, aby se naši zaměstnanci cítili svobodně, ale zároveň odpovědně a s tím přistupovali k realizaci všech zakázek.

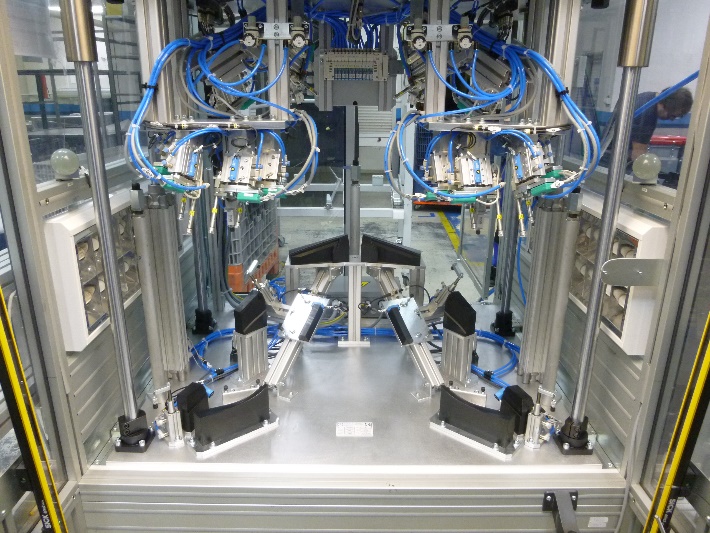

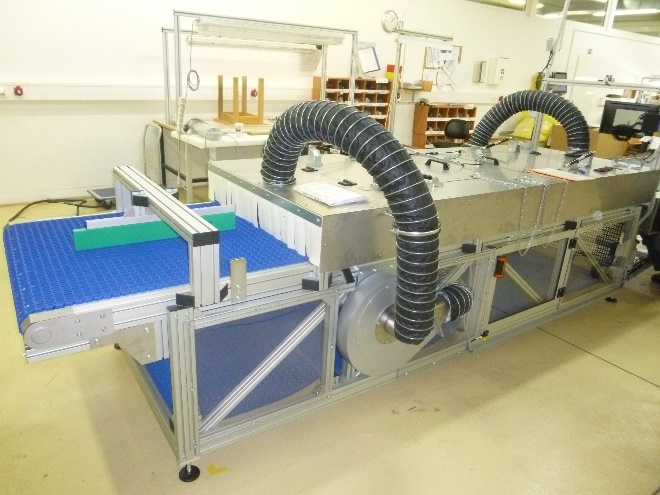

Jak to u nás vypadá

Ukázky z realizace

Aktuálně z Montekord

Veletrh robotických příležitostí 2023 od FANUCU

VELETRH ROBOTICKÝCH PŘÍLEŽITOSTÍ 2023 Společnost Montekord Machines s.r.o. [...]

Měření a testování

Kontrolní přípravek výparníků – automatizace Poloautomatický přípravek pro [...]

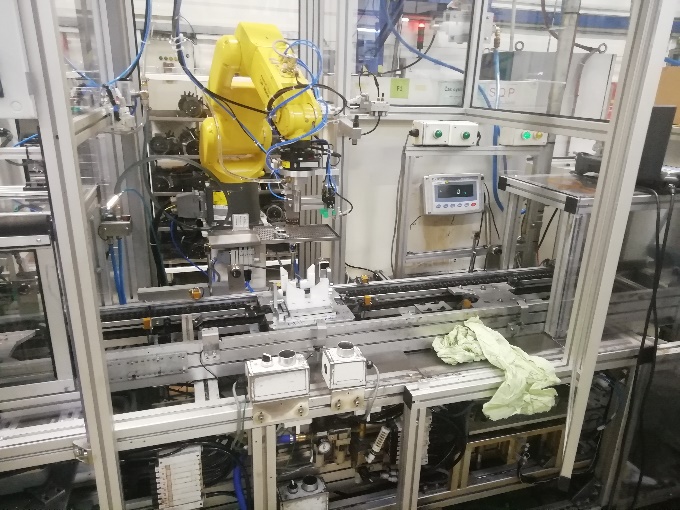

Pracovní stanice

Robotické plnění kompresorů olejem v lince Integrace robotické buňky [...]

Manipulace

Robotické hnízdo obsluhy brusek Robotická obsluha a mezioperační [...]

Výrobní linky a obsluhy strojů

Robotické dávkování hliníkových odlitků do CNC strojů Doplnění [...]